| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : YDX

Model Number : YDX-S1

Certification : CE ISO SGS

Place of Origin : CHINA,QINGDAO

MOQ : 10-10000 square meters

Price : $30.00-$65.00

Payment Terms : T/T

Supply Ability : 10000 tons/month

Delivery Time : 20-30 works days

Packaging Details : Exported standard packing

Grade : Q235 Q235B Q345,S355,Hot Rolled Steel,Q345B,ASTM

Drawing design : AutoCAD,3D

Roofing : Sandwich Panel, Single Steel Sheet,EPS sandwich panel

Wall : Color Steel Sheet Sandwich Panel

Structure Type : Frame

Frame Type : Steel Frame

Earthquake Resistance : Strong

Windows : Aluminum

Seismic Design : High Seismic Zone

Installation Time : Short

Aesthetics : Modern

Construction Type : Frame

Cost : Moderate

Product Resistance : Corrosion Resistant

Finish : Galvanized/Painted/Cladding

Roof : Glass Wool, EPS, PU

Product Fire Resistance : Fireproof

Door : Sliding Door or Rolling Door

· Load Calculation: Accurately calculate dead loads (e.g., self-weight), live loads (e.g., goods weight), wind loads, and snow loads to ensure structural safety.

· Span and Height: Design the span and height reasonably based on warehouse usage to ensure space utilization and structural stability.

· Seismic Design: In earthquake-prone areas, adopt flexible joints and energy-dissipating devices to enhance seismic performance.

· Fire Protection: Use fireproof coatings or boards to ensure the steel structure meets the required fire resistance limits.

· Anti-Corrosion Treatment: Apply hot-dip galvanizing or painting to prevent steel corrosion in humid environments.

· Ventilation Design: Install a proper ventilation system to ensure air circulation and prevent goods from dampness or spoilage.

· Lighting Design: Utilize skylights or side windows to introduce natural light and reduce lighting energy consumption.

· Construction Quality Control: Strictly follow design drawings and standards to ensure the quality of key processes like welding and bolting.

· Maintenance Plan: Develop a regular inspection and maintenance plan to promptly repair damaged or aging components and extend service life.

· Type: Commonly used steels include Q235 and Q345, with the appropriate strength grade selected based on load and design requirements.

· Specifications: Choose steel sections such as I-beams, H-beams, and angle steel based on structural design.

· Welding Materials: Select welding rods or wires compatible with the base metal to ensure welding quality.

· Bolted Connections: Use high-strength bolts to ensure the reliability and stability of joint connections.

· Fireproof Materials: Such as fireproof coatings and boards, used to improve the fire resistance of steel structures.

· Anti-Corrosion Materials: Such as hot-dip galvanizing and anti-rust paint, used to enhance the corrosion resistance of steel.

· Insulation Materials: Such as rock wool and glass wool, used to improve the thermal insulation of the warehouse.

| Product Application | |||

| Light Frame Steel Construction Hangar Design Prefabricated Steel Structure Factory Building Workshop warehouse | |||

| A pre-engineered steel building is a modern technology where the complete designing is done at the factory and the building components are brought to the site and then fixed/jointed at the site, all is bolt connection, no need any welding! | |||

| An efficiently designed pre-engineered building can be lighter than the conventional steel buildings by up to 30%. Lighter weight equates to less steel and potential price savings in structural framework. | |||

| SPECIFICATION FOR STEEL STRUCTURE BUILDING | |||

| Main Steel Frame | Steel Column & Beam | 1. Material: Q345B (S355JR) or Q235B(S235JR)/ Welded/Hot Rolled H section steel | |

| 2. Surface: Hot Dip Galvanized or Painted; | |||

| 3. Connection: All Bolts Connection; | |||

| Supporting System | Roof Purlin | C or Z Section Steel, Q235B | |

| Wall Purlin | C or Z Section Steel, Q235B | ||

| Bracing | Steel Rod, Q235B | ||

| Cross Support | Steel Rod, Q235B | ||

| Column Support | Angle Steel; Steel Rod; Q235B | ||

| Angle Brace | Angle steel,Q235B | ||

| Tie Bar | Steel Pipe,Q235B | ||

| Roof & Wall System | 1. Single Colorful Corrugated Steel Sheet; Thickness: 0.3-0.8mm | ||

| 2. Sandwich Panel with EPS, Rock Wool, Fiberglass,PU; Thickness: 50-150mm; | |||

| Accessories | Door | Sliding; Rolled Up Door (Manual/Auto) | |

| Window | Aluminum Alloy; PVC; | ||

| Downspout | PVC pipe; | ||

| Gutter | Galvanized Steel Sheet; Stainless Steel | ||

| Ventilator | Stainless Steel Turbine Ventilator | ||

| Skylight Belt | FRP or PC semi-transparent Skylight Belt | ||

| Flash | Color Steel Sheet | ||

| Fittings | Anchor Bolt; High Strength Bolt; Standard Bolt, Self-tapping nail etc | ||

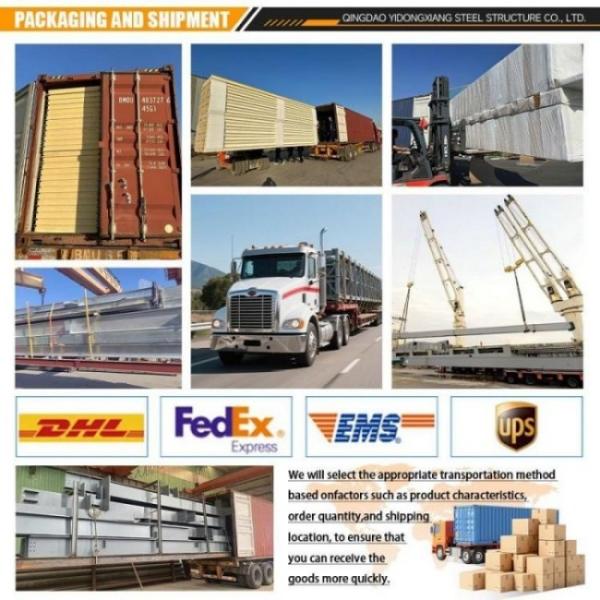

Packing & Loading:

| 1 | Location (where will be built?) | _____country, area |

| 2 | Size: length*width*height | _____mm*_____mm*_____mm |

| 3 | wind load (max. wind speed) | _____kn/m2, _____km/h, _____m/s |

| 4 | snow load (max. snow height) | _____kn/m2, _____mm |

| 5 | anti-earthquake | _____level |

| 6 | brickwall needed or not | If yes, 1.2m high or 1.5m high |

| 7 | thermal insulation | If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested; . if not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former |

| 8 | door quantity & size | _____units, _____(width)mm*_____(height)mm |

| 9 | window quanity & size | _____units, _____(width)mm*_____(height)mm |

| 10 | crane needed or not | If yes, _____units, max. lifting weight____tons; max. lifting height _____m |

|

|

S355JR S235JR Architectural Steel Buildings Steel Structure Storage Warehouse Images |